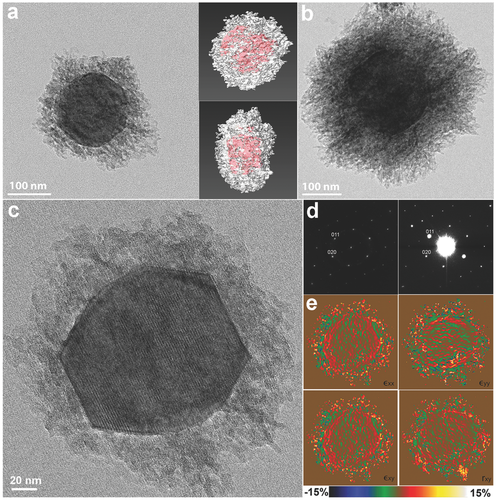

Direct synthesis of hierarchical zeolites currently relies on the use of surfactant‐based templates to produce mesoporosity by the random stacking of 2D zeolite sheets or the agglomeration of tiny zeolite grains. The benefits of using nonsurfactant polymers as dual‐function templates in the fabrication of hierarchical zeolites are demonstrated. First, the minimal intermolecular interactions of nonsurfactant polymers impose little interference on the crystallization of zeolites, favoring the formation of 3D continuous zeolite frameworks with a long‐range order. Second, the mutual interpenetration of the polymer and the zeolite networks renders disordered but highly interconnected mesopores in zeolite crystals. These two factors allow for the synthesis of single‐crystalline, mesoporous zeolites of varied compositions and framework types. A representative example, hierarchial aluminosilicate (meso‐ZSM‐5), has been carefully characterized. It has a unique branched fibrous structure, and far outperforms bulk aluminosilicate (ZSM‐5) as a catalyst in two model reactions: conversion of methanol to aromatics and catalytic cracking of canola oil. Third, extra functional groups in the polymer template can be utilized to incorporate desired functionalities into hierarchical zeolites. Last and most importantly, polymer‐based templates permit heterogeneous nucleation and growth of mesoporous zeolites on existing surfaces, forming a continuous zeolitic layer. In a proof‐of‐concept experiment, unprecedented core–shell‐structured hierarchical zeolites are synthesized by coating mesoporous zeolites on the surfaces of bulk zeolites.

Direct synthesis of hierarchical zeolites currently relies on the use of surfactant‐based templates to produce mesoporosity by the random stacking of 2D zeolite sheets or the agglomeration of tiny zeolite grains. The benefits of using nonsurfactant polymers as dual‐function templates in the fabrication of hierarchical zeolites are demonstrated. First, the minimal intermolecular interactions of nonsurfactant polymers impose little interference on the crystallization of zeolites, favoring the formation of 3D continuous zeolite frameworks with a long‐range order. Second, the mutual interpenetration of the polymer and the zeolite networks renders disordered but highly interconnected mesopores in zeolite crystals. These two factors allow for the synthesis of single‐crystalline, mesoporous zeolites of varied compositions and framework types. A representative example, hierarchial aluminosilicate (meso‐ZSM‐5), has been carefully characterized. It has a unique branched fibrous structure, and far outperforms bulk aluminosilicate (ZSM‐5) as a catalyst in two model reactions: conversion of methanol to aromatics and catalytic cracking of canola oil. Third, extra functional groups in the polymer template can be utilized to incorporate desired functionalities into hierarchical zeolites. Last and most importantly, polymer‐based templates permit heterogeneous nucleation and growth of mesoporous zeolites on existing surfaces, forming a continuous zeolitic layer. In a proof‐of‐concept experiment, unprecedented core–shell‐structured hierarchical zeolites are synthesized by coating mesoporous zeolites on the surfaces of bulk zeolites.